Industrial Plastic Moulding Machine

Price 250000 INR/ Piece

Industrial Plastic Moulding Machine Specification

- Product Type

- Plastic Processing

- Power Source

- Electricity

- Operating Type

- Automatic

- Surface Treatment

- Coated

- Color

- Yellow-Grey

- Warranty

- 1 Years

- Usage & Applications

- Industrial

Industrial Plastic Moulding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial Plastic Moulding Machine

Industrial Plastic Moulding Machine creates plastic products through injection moulding. The machine process involves melting plastic pellets or granules in its hopper and injecting the molten material into a mould under high pressure. The molten plastic takes on the shape of the mould cavity and is then cooled and solidified. Industrial Plastic Moulding Machine can produce a wide variety of plastic parts, ranging from small intricate components to larger consumer products like automobile parts. These machines are highly automated and precise, and can run continuously for long periods of time, producing high volumes of identical parts.

| Machine Type | Injection Blow Molding |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulding Machine Category

Pani Puri Batasa Making Machine

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Pani Puri and Batasa production

Color : Blue and Stainless Steel Finish

Power Source : Other, AC Power Supply

Surface Treatment : Other

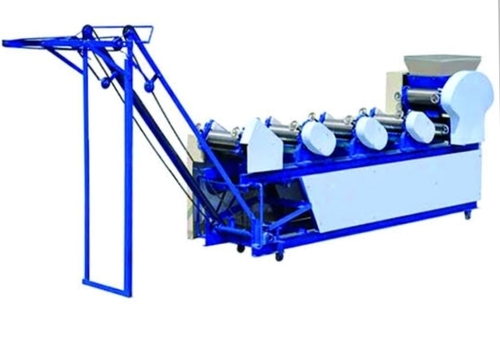

Fully Automatic Noodles Making Machine

Price 365000 INR / Thousand

Minimum Order Quantity : 1 Unit

Usage & Applications : Noodles Production

Color : Blue and White

Power Source : Other, Electric

Surface Treatment : Other

Spice Grinder Machine

Price 23900 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Color : Silver

Power Source : Electricity

Surface Treatment : Coated

Mitti Steel Bamboo Round Stick Making Machinery

Price 865000 SEK (kr) / Thousand

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Color : Blue And White

Power Source : Electricity

Surface Treatment : Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS